ALSTOM N897164611M High Performance Control Module

Interface type: Equipped with standard electrical interfaces, such as Ethernet interfaces, it can achieve high-speed and long-distance data transmission, with transmission rates up to 10/100Mbps or even higher, meeting communication scenarios with high data volume and real-time requirements; The RS-232 interface is suitable for short distance, low-speed data communication and is commonly used to connect debugging equipment, simple sensors, etc; The RS-485 interface has stronger anti-interference ability and longer transmission distance, which can stably transmit data in the complex electromagnetic environment of industrial sites, and can connect up to multiple node devices. The CAN bus interface plays an important role in industrial control networks due to its high-speed, reliable, and multi master communication characteristics, and is suitable for connecting devices that require extremely high real-time and reliability.

Environmental adaptability parameters

Working temperature range: It can work stably in harsh temperature environments, with a working temperature range from -20 ° C to+60 ° C. This allows the module to operate normally in cold northern winter outdoor equipment and hot southern summer high-temperature workshops without the need for additional temperature control equipment, greatly improving its applicability in different regions and working environments.

Storage temperature range: Even in non working conditions, the module can adapt to a wider range of temperature storage conditions, with a storage temperature range of -55 ° C to+125 ° C. This ensures that the module will not be damaged due to changes in environmental temperature during transportation, inventory, and other processes, extending its service life and reliability.

Humidity adaptability: It also has good adaptability to humid environments and can work normally in environments with relative humidity of 5% to 95% and no condensation phenomenon. Whether in humid coastal areas or production workshops in industries such as chemical and textile with high humidity, modules can perform tasks stably, ensuring the continuous operation of the system and preventing faults such as short circuits and corrosion caused by humidity issues.

Dimensions and physical characteristics

Size: The module adopts a compact design with external dimensions of 20cm x 20cm x 20cm. This small volume allows it to be easily integrated into various space limited control panels, control cabinets, or vehicle systems, without occupying too much installation space, facilitating system layout and design.

Weight: The weight is about 10kg, which ensures the stability of the electronic components and structure inside the module, and is not too heavy. It is easy to install, disassemble, and maintain, reducing the difficulty and labor intensity of manual operation.

Protective design: The shell is made of sturdy and durable materials, with a certain level of protection, which can effectively prevent dust and foreign objects from entering, and also provide good mechanical protection for internal electronic components. In complex industrial environments such as mines and cement plants with large amounts of dust, it is possible to ensure the normal operation of modules and reduce the occurrence of failures caused by external factors.

Application Fields

Railway transportation field

Train tracking and signal management: In the railway network, accurate tracking of trains and intelligent management of signals are achieved by collecting real-time information such as train position and speed, and communicating with the signal system. Ensure safe operating intervals between trains, control the display of signal lights reasonably, and guarantee the efficiency and safety of railway transportation.

Security mechanism control: Integrate automatic train protection (ATP) and other safety functions to monitor and control the real-time operation status of the train. Once abnormal situations are detected, such as overspeed or signal intrusion, corresponding safety braking measures will be immediately triggered to ensure the safe operation of the train and prevent accidents from occurring.

On board system diagnosis and communication: responsible for data collection, processing, and communication of the train's onboard system, transmitting various operating parameters of the train, such as vehicle status, equipment failure information, etc., to the central control system in real time, facilitating staff to timely understand the train's operating conditions, conduct remote diagnosis and maintenance, and improve the availability and reliability of the train.

Industrial automation field

Production line automation control: It can be used to control the start stop, speed adjustment, material handling system operation, and robot arm movements of various industrial production lines. By precise control signal output, the automation and intelligence of the production process can be achieved, improving production efficiency, reducing labor costs, and enhancing the consistency and stability of product quality.

Data Collection and Processing Center: As the core module of data collection and processing in industrial automation systems, it collects sensor data from various links on the production line, such as temperature, pressure, flow rate, position, etc., and performs real-time analysis and processing. Based on the processing results, optimize and adjust the production process to achieve refined control, improve resource utilization and production efficiency.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

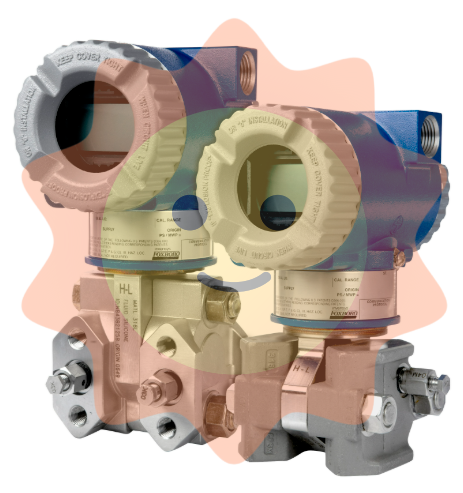

- YOKOGAWA

- TRICONEX

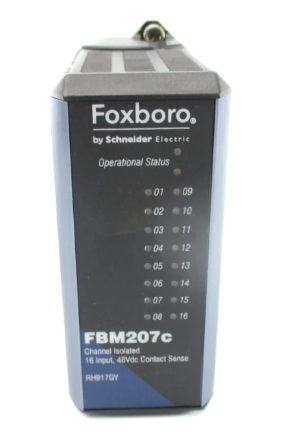

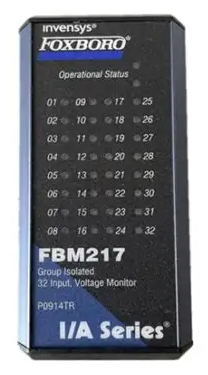

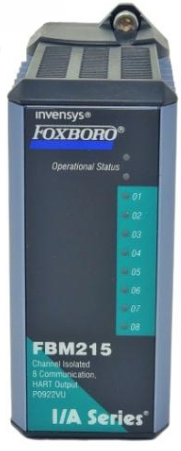

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com