Bender LifeGuard ® LG2 series protective panel

Bender LifeGuard ® LG2 series protective panel

Product Overview

Bender LifeGuard ® The LG2 series is an industrial grade ground fault protection panel launched by Bender, a German company. Its core function is to monitor the ground fault current in the circuit, quickly cut off the load power supply when the current reaches the trip threshold, and avoid safety risks such as electric shock and arc flashover. The product is compatible with various voltage and phase industrial circuits, providing flexible installation forms and operation methods, complying with UL 508A industrial control panel standards, and widely used in factory equipment, industrial control systems, and other scenarios.

Core parameters and specifications

Category specific parameters

Adaptation voltage 120VAC、208VAC、208/120VAC、240/120VAC、480VAC、480/277VAC、600VAC、600/347VAC

Circuit phase 1ph (2w/3w), 3ph (3w/4w)

Rated current < 100A, 100A

Release level digital display fixed 6mA

Shell type NEMA 4X polycarbonate, NEMA 4X stainless steel, backplate only (requires self provided cabinet)

Dimensions (length × width × depth) < 100A: 305 × 254 × 152mm (12 "× 10" × 6 "); 100A: 406 × 356 × 203mm (16" × 14 "× 8")

The wire requirement is only copper wire; Rated at 60 ℃ (140 ℉) or above for<100A; 100A requires a rated temperature of 75 ℃ (167 ℉) or above

Installation and wiring specifications

(1) Installation requirements

Installation of shell:

Provide wall mounted mounting feet and follow separate wall mounting instructions;

It is recommended to use NEMA 4X or higher grade connectors at the bottom of the casing for cable perforation to maintain the protection level.

Only for backplate installation:

It needs to be installed in a compliant cabinet, with vertical clearance requirements of 152mm (6 ") for<100A and 203mm (8") for 100A;

Fix with 4 # 10 screws, with a mounting hole diameter of 6.4mm (1/4 ").

(2) Wiring rules

Installation must be carried out by licensed electricians, following local, state, and national electrical regulations;

All active conductors (including neutral wire N) need to pass through a current transformer and be connected to the incoming side of the contactor;

Connect the load or protected branch to the outgoing side of the contactor;

The incoming and load grounding wires must be connected to the backplane grounding terminal and must not pass through the current transformer;

The number of conductors and wiring diagrams corresponding to different voltages are as follows:

Reference wiring diagram for voltage specification, number of conductors (excluding grounding)

120 VAC 1ph/2w(L1、N) Figure W1

208 VAC 3ph/3w(L1、L2、L3) Figure W2

208/120 VAC 3ph/4w(L1、L2、L3、N) Figure W3

240/120 VAC 1ph/3w(L1、L2、N) Figure W4

480 VAC 3ph/3w(L1、L2、L3) Figure W2

480/277 VAC 3ph/4w(L1、L2、L3、N) Figure W3

600 VAC 3ph/3w(L1、L2、L3) Figure W2

600/347 VAC 3ph/4w(L1、L2、L3、N) Figure W3

Operation process and functions

(1) Basic operation (non digital version)

Power on: Close the circuit breaker/isolation switch on the incoming side, and the green POWER ON LED will light up when there is no ground fault;

Test (trip level A/F):

Press and hold the TEST button for ≥ 2 seconds, the device will trip, the red CIRCUIT TRIPPED LED will light up, and the load will be powered off;

After internal self check for about 10 seconds, press and hold the RESET button for ≥ 1 second to reset the device and restore power supply;

Test (trip level D/E):

Press and hold the TEST button for ≥ 2 seconds, the device will trip, and the red LED will light up;

Press and hold the RESET button for at least 1 second to reset the device and restore power supply.

(2) Digital display operation (model ending with "- N-D")

Additional support for real-time display of ground fault current, LED bar chart indicating tripping risk;

Test: Press and hold the TEST button until the display screen shows "tES", and the device will trip within 15 seconds;

Reset: Press and hold the RESET button until the display screen shows "rES" to restore power supply;

Remote function:

Can connect to MK1500-D remote indicator, copy local testing/reset function;

Use AWG 18 shielded RS-485 cable connection and turn on the "R" switch on the grounding fault module;

MK1500-D requires an external power supply of 100-240VAC, 50/60Hz.

Safety and Compliance

Before installation, all power sources must be disconnected to avoid the risk of electric shock and arc flashover;

Separate isolation switches, branch protections, and/or overload relays need to be configured;

The three-phase three wire system can adopt direct grounding or resistance grounding methods;

Equipment troubleshooting and parameter adjustment should refer to the user manual of the protective relay.

Key issue

Question 1: LifeGuard ® What is the core protection function of the LG2 series? What are the differences in adaptation scenarios for different specifications?

Answer: The core protection function is to monitor the grounding fault current in the circuit in real time through current transformers. When the current reaches the tripping threshold, the load power supply is quickly cut off to prevent risks such as electric shock and equipment damage. The differences in adaptation scenarios for different specifications are as follows: ① Rated current<100A: Small size (305 × 254 × 152mm), suitable for small and medium power industrial equipment and branch circuit protection; ② Rated current 100A: larger size (406 × 356 × 203mm), suitable for high-power main circuits and heavy-duty equipment power protection; ③ Digital display version: Fixed 6mA trip level, real-time display of fault current, suitable for scenarios with requirements for protection accuracy; ④ Backplane only: needs to be installed inside the cabinet and is suitable for integrated industrial control systems.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

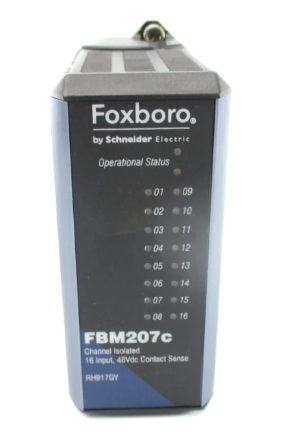

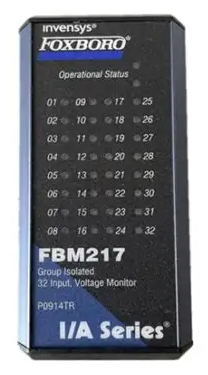

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com