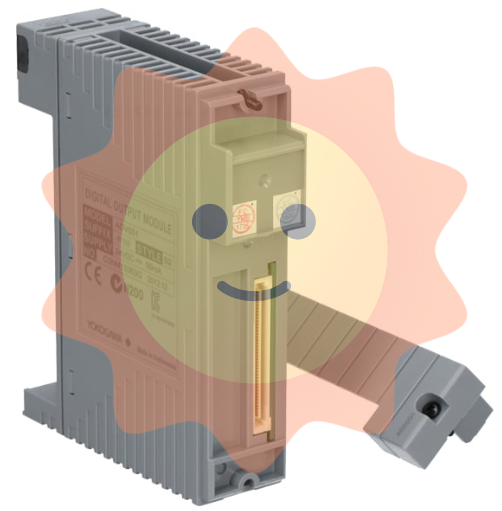

YASKAWA U1000 series 24V power supply options (PS-U10L/PS-U10H)

Operation verification and troubleshooting

1. Run verification steps

After installation and wiring are completed, the following steps should be taken to verify whether the option functions properly:

Power on the main circuit of the driver and confirm that the external 24V power supply has been connected to the TB1 terminal of the option, and that the option is properly connected to the driver cable;

Disconnect the power supply of the main circuit of the drive, and the option should supply power to the control circuit of the drive;

Observe the red LED indicator light on the option. If it lights up, it indicates that the option is working properly;

When checking the digital operator of the drive, it should briefly display "Fdv" or "AUv" (undervoltage prompt) for about 10 seconds. This prompt is a normal phenomenon, indicating that the control circuit has been powered through the option 🔶 2-413;

2. Handling of abnormal situations

If the option LED does not light up: check if the external 24V power supply is normal (voltage range 19.2-28.8V), if the TB1 terminal wiring is loose or reversed, and if the option is in good contact with the driver cable;

If there is no "Fdv/AUv" prompt on the operator: first confirm that the wiring is correct, then check if the driver parameter o2-19 is set correctly. If it is still abnormal, it may be a problem with the option or driver, and contact Yaskawa after-sales service;

In addition, Table 3 (Power Supply and Control Circuit) of the document specifies the operation of the control circuit and driver under different power states, which can be used to assist in fault diagnosis:

Driver main circuit power options, power supply status, driver control circuit operation status, driver operation possibility

ON, ON, can run normally

ON/OFF can run

OFF/ON can access data (parameters/faults) but cannot run

OFF: Stop running and cannot run

Core Security Standards

(1) Electrical safety

Prohibited live operation: During installation, wiring, and maintenance, all power sources must be disconnected and the capacitor must be discharged (at least 5 minutes). The CHARGE light must be turned off before operation, otherwise it may cause electric shock death or serious injury 🔶 2-133;

Authorization operation requirements: Only authorized personnel who have received training are allowed to install and maintain. Unauthorized personnel operation may cause safety accidents;

Prohibited from modifying equipment: It is not allowed to modify the driver body or option circuit without authorization. Modifying will result in the expiration of the warranty, and Yaskawa will not be responsible for any damage caused by this;

(2) Fire prevention and equipment protection

Terminal torque requirements: All terminal screws must be tightened to the specified torque (such as TB1 terminal 0.22-0.25N · m, screw 0.5-0.7N · m). Too loose may cause poor contact, heat generation, and fire, while too tight may damage the terminals 🔶 2-149;

Static electricity protection: When in contact with options, drivers, or circuit boards, it is necessary to follow the ESD (electrostatic discharge) protection process (such as wearing an anti-static wristband) to avoid static electricity damaging the circuit;

Environmental restrictions: It is prohibited to expose options or drivers to halogen disinfectants, and they should not be stored in fumigated wooden packaging to avoid chemical damage to electrical components

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

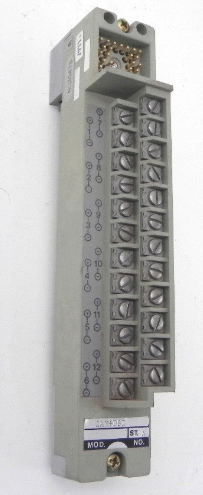

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

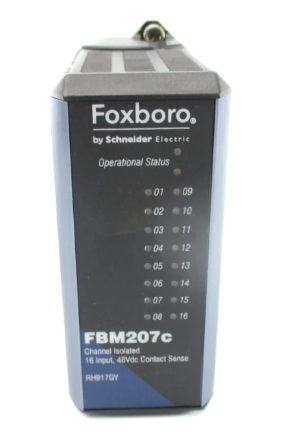

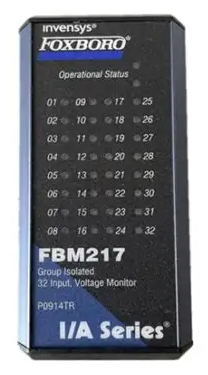

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com