WESTINGHOUSE MAX-VH ™/ MAX-VHP ™ Series vertical hollow shaft induction motor

VHP1504 (150 HP): Full load efficiency 95.8%, power factor 86.0%, 460V full load current 171A, downward thrust 10700 LBS, transport weight 1815 LBS.

VHTP8004 (800 HP): TEFC protection, full load efficiency of 96.2%, power factor of 86.0%, 460V full load current of 904A, downward thrust of 10100 LBS, transport weight of 9220 LBS.

Core advantages: NEMA high-efficiency certification, lower energy consumption, suitable for industrial scenarios with strict energy efficiency requirements (such as data centers and high-end manufacturing).

(2) Medium voltage series (2300V/4000V)

1. VHKP high thrust series

Power coverage: 200-1000 HP, speed 1200/1800 RPM, frame number 449TP-5810P.

Example of core parameters:

VHKP5004 (500 HP, 1800 RPM): Full load efficiency of 95.0%, power factor of 87.6%, downward thrust of 30900 LBS, transport weight of 3980 LBS.

VHKP10004 (1000 HP, 1800 RPM): Full load efficiency of 95.0%, power factor of 87.3%, downward thrust of 30100 LBS, transport weight of 6510 LBS.

Applicable scenarios: heavy-duty equipment such as large industrial pumps and compressors that require high thrust and high voltage power supply.

2. VHKTP TEFC high thrust series

Power coverage: 200-700 HP, speed 1200/1800 RPM, frame number 449TP-5810P.

Core features: IP55 protection, suitable for harsh environments, with a maximum downward thrust of 22300 LBS, designed specifically for medium voltage heavy loads and high protection requirements.

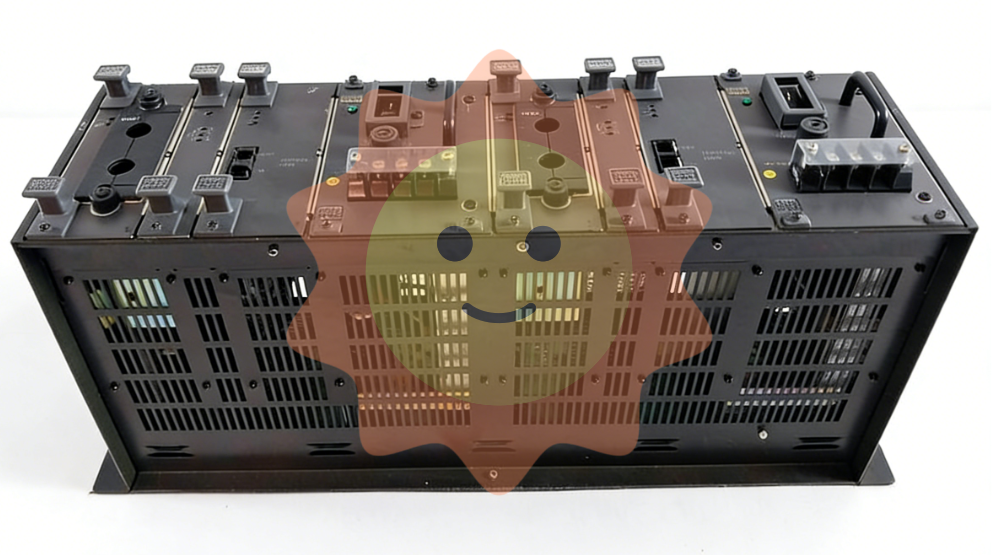

Core structure and key component design

(1) Bearing and lubrication system

1. Bearing configuration (graded by frame number)

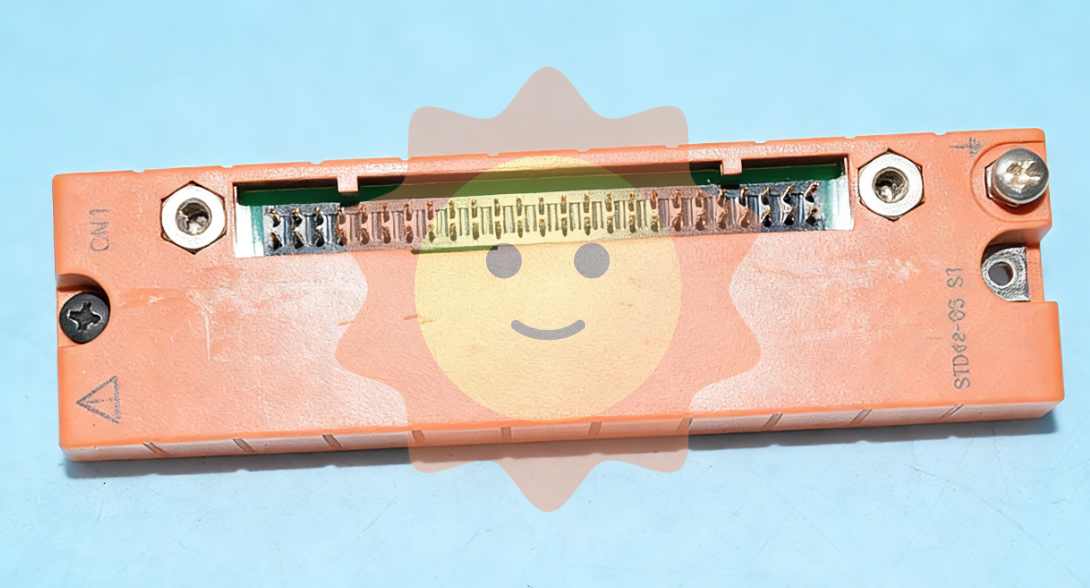

Frame number range thrust bearing (upper) guide bearing (lower)

213TP-286TP grease refillable angular contact bearing, filled with Polyrex EM grease pre filled grease double shielded rolling bearing

324TP-5810P oil lubricated angular contact/spherical bearing with oil level sight glass (maximum 300% thrust adaptation) bracket installation vacuum degassing open bearing, with grease release valve

2. Requirements for lubricating media

Guide bearing: Lithium based mineral grease (Multemp SRL) or Polyrex EM grease.

Thrust bearing (324TP-449TP): Turbine oil, viscosity 300 S.S.U. @ 100 ° F.

Lubrication key: Oil lubricated models need to regularly check the oil level, while grease lubricated models need to regularly replenish grease according to operating conditions to avoid dry friction damage.

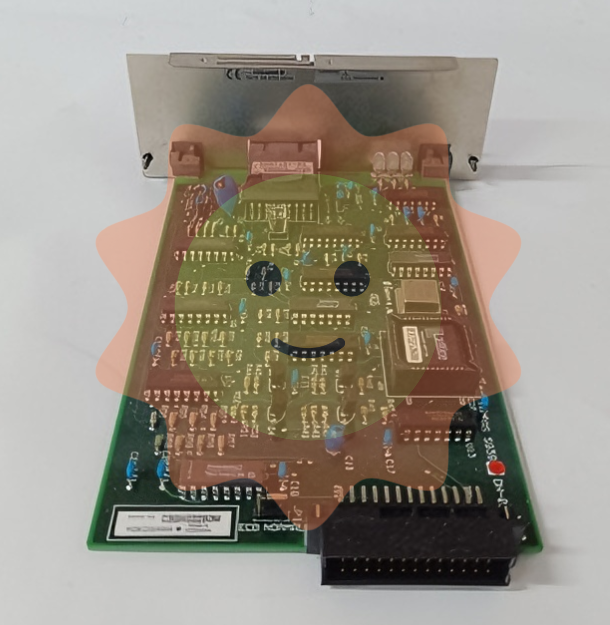

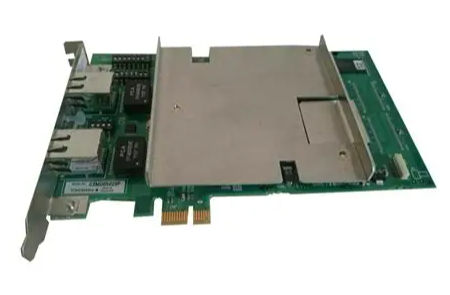

(2) Electrical system design

1. Wiring and terminals

Lead terminal: 210TP-405TP has 12 leads (230V supports partial winding start, 230V/460V supports star delta start); 444TP and above are 6-lead wires (460V supports partial winding startup).

Junction box: made of cast iron material, can rotate 90 °, with threaded interface, convenient for external conduit access, built-in grounding terminal (including P-Base grounding terminal).

2. Protection and safety

Winding protection: F-class insulation system, excellent temperature resistance, suitable for frequency converter pulse impact.

Hazardous environment adaptation: TEFC models have passed CSA certification and can be used in Class 1, Div 2, Group B, C, D scenarios, with a minimum temperature level of T3.

(3) Highlights of Mechanical Structure

1. High rigidity frame

Adopting high-grade cast iron integrated casting, the upper bracket with frame number 449TP-5810P is designed with an integrated oil tank, balancing structural strength and lubrication storage requirements.

The flange bracket size complies with NEMA MG1-18-238 standard, ensuring installation compatibility and transmission stability.

2. Hollow shaft design

1045 carbon steel material, hollow structure reduces weight while ensuring strength, suitable for direct coupling transmission, shaft diameter size graded according to frame number (BX size 1.001-2.501 inches), strict tolerance control (≤ 1.5 inches:+0.001/-0.000 inches; > 1.5 inches:+0.0015/-0.000 inches).

3. Auxiliary components

Standard configuration: wedge key, non reversing pawl (NRR, ball type spark free design), heavy-duty beryllium copper ball to prevent equipment from rotating in the opposite direction and causing damage.

Optional configurations: stable liner, alternative coupler, customized P-Base size.

Installation and operation specifications

(1) Installation requirements

1. Environmental conditions

Temperature: -15 ℃~40 ℃ (WP1 type), TEFC model is suitable for hazardous environments (Class 1, Div 2).

Humidity: ≤ 80% RH (no condensation).

Altitude: ≤ 3300 feet (approximately 1006 meters).

Installation method: Flange installation (IM3011), the P-Base base needs to be matched with the corresponding model according to the frame number (such as 210TP with 31103F412X1C0), and it needs to be machined by the factory before installation.

2. Coupling and fixation

Coupling kit: Each motor comes standard with one set of couplers, and the BX size is adapted according to the frame number (such as 213TP standard BX=1.001 inches). Separate procurement requires pricing according to the list.

Fixed requirement: The anchor bolts should be tightened according to ISO metric thread to ensure no vibration displacement during the transmission process.

(2) Operating standards for operation

1. Check before startup

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

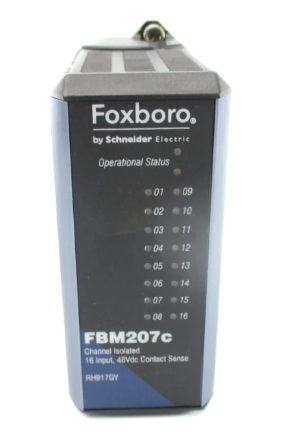

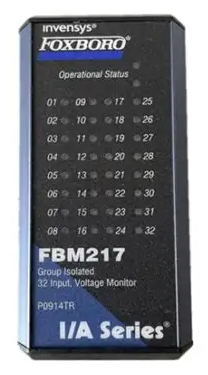

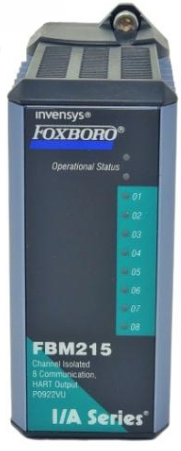

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

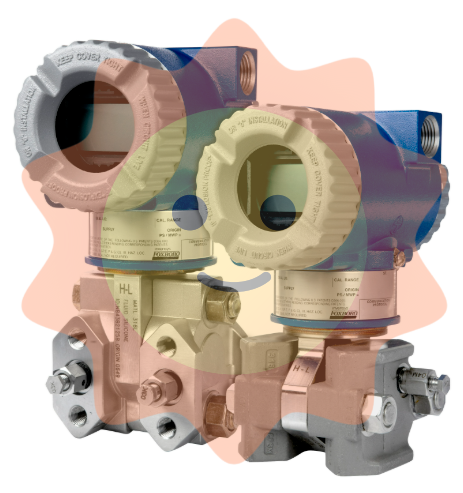

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com