WESTINGHOUSE MAX-VH ™/ MAX-VHP ™ Series vertical hollow shaft induction motor

Electrical inspection: power supply voltage fluctuation ≤ ± 10%, frequency fluctuation ≤ ± 5%, three-phase voltage balance; The insulation resistance meets the standard (F-class insulation ≥ 100 M Ω @ 40 ℃).

Mechanical inspection: The oil level of the oil lubricated model is within the normal range of the sight glass, and there is no grease leakage in the grease lubricated model; The bearing is not stuck, and the hollow shaft rotates smoothly; The function of the non reversing pawl is normal.

Protection inspection: WP1 type protective net is undamaged, TEFC model is well sealed, and there is no foreign object intrusion.

2. Operation monitoring

Key parameters: Full load current not exceeding rated value, three-phase current imbalance ≤ ± 5%; Bearing temperature ≤ 95 ℃, winding temperature ≤ 105 ℃ (S.F.1.15).

Exception handling: If overspeed or over torque conditions occur, it is necessary to ensure that the duration does not exceed the specified limit; When abnormal noise or increased vibration occurs, immediately stop the machine to investigate bearing or coupling issues.

3. Shutdown specifications

Normal shutdown: First reduce the load, then cut off the power. TEFC models need to wait for the fan to completely stop before shutting down the cooling system.

Long term shutdown: Rotate the hollow shaft regularly (at least 1 turn per month) to avoid bearing corrosion; Oil lubricated models require draining the oil tank, while grease lubricated models require replenishing new grease.

Maintenance and upkeep system

(1) Maintenance cycle and core projects

Key operational points for core projects in the maintenance cycle

Daily visual inspection and oil level monitoring check that the motor surface is free of damage, grease and oil leakage; The oil level of the lubrication model is at the center position of the sight glass

Weekly current/temperature monitoring+abnormal noise investigation records three-phase current and bearing temperature; Listen to the sound of the motor running, no abnormal vibration or friction sound

Monthly bearing maintenance+junction box inspection, grease lubrication for machine models (quantified by bearing model); The terminal of the junction box is not loose or oxidized

Measure the insulation resistance of the winding with a 500VDC megohmmeter every quarter to ensure it is ≥ 100 M Ω at 40 ℃

Annual comprehensive disassembly inspection and cleaning of winding dust; Check the wear of the bearings and replace them if necessary; Check for no reverse pawl function

Deeply maintain and replace bearings and lubricating media every 3 years; Check the connection between the rotor guide bar and the end ring; Re tighten all bolts

(2) Key component maintenance details

1. Bearing maintenance

Lubricating with grease: Add grease according to the bearing model (such as 6312C3, add 40g of grease), and run without load for 10-30 minutes after adding grease to discharge the old grease.

Oil lubrication: Replace the turbine oil once a year, rinse the oil tank with a cleaning agent before replacement to ensure that there are no impurities left; Timely replenish when the oil level is below the minimum mark to avoid dry friction.

2. Winding maintenance

Cleaning: Use compressed air (pressure ≤ 4 kg/cm ²) to blow away dust on the surface of the winding, wipe off oil stains with neutral cleaner, and prohibit the use of chlorine containing solvents.

Moisture prevention: When the machine is shut down for a long time, use the space heater to maintain the winding temperature 3 ℃ higher than the dew point to prevent condensation from damaging the insulation.

3. Maintenance of Non Reversing Claw (NRR)

Regularly check the engagement between the pawl and ratchet, ensuring no jamming or wear; Replace the pawl ball bearings every 3 years to avoid reverse rotation failure.

Selection Guide and Application Scenarios

(1) Selection core logic

Power matching: Select the motor power based on 1.2 times the rated load power, ensuring redundancy (such as selecting a 60 HP motor for a 50 HP load).

Voltage adaptation: Choose 230V/460V for low voltage scenarios (≤ 400 HP) and 2300V/4000V for medium voltage scenarios (≥ 200 HP).

Protection level: Choose WP1 (IP23) for ordinary industrial environments, and TEFC (IP55) for humid/dusty/hazardous environments.

Energy efficiency requirement: MAX-VH is selected for general scenarios ™, Choose MAX-VHP for energy-saving scenarios (such as continuous operation equipment) ™ (NEMA high efficiency level).

Thrust adaptation: Select the corresponding frame number for downward thrust according to the load (e.g. 444TP frame for 10000 LBS thrust).

(2) Typical application scenarios

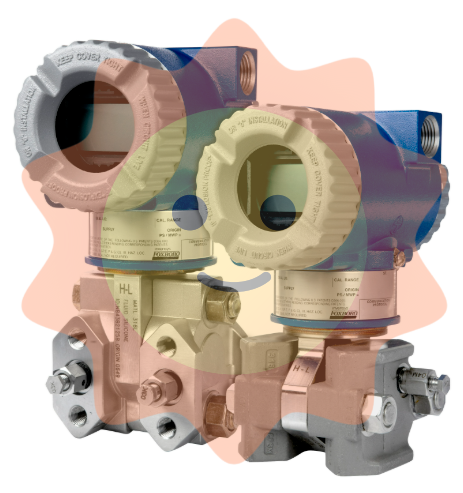

Industrial pumps: fire pumps, sewage pumps, chemical centrifugal pumps (especially large pump sets that require high thrust and direct coupling).

Compressors: air compressors, refrigeration compressors, suitable for continuous operation conditions.

General machinery: fans, transmission gearboxes, suitable for scenarios with high requirements for speed stability.

Special environments: hazardous environments such as petrochemicals and mines (TEFC models), high temperature/high humidity industrial workshops (WP1 models).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

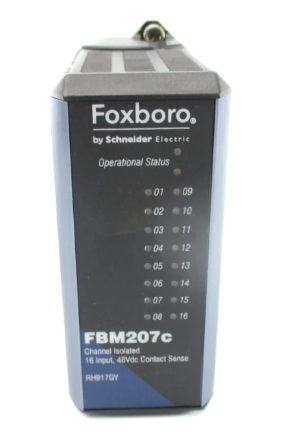

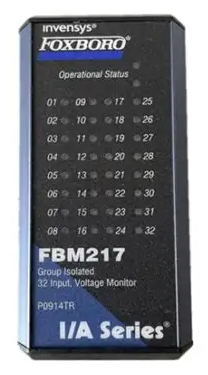

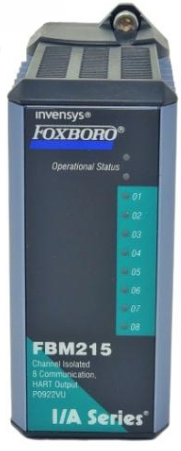

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com