Watlow PM LEGACY ™ Limit controller

Model specifications: available in two panel sizes: 1/32 DIN (PM3) and 1/16 DIN (PM6), supporting AC/DC dual power supply mode and compatible with multiple input/output configurations.

Core advantages: simple and easy to operate menu, PID self-tuning function, multi bus communication support, FM certified over/under temperature protection, three-year warranty, and features such as touch safe packaging, waterproof and dustproof (NEMA 4X/IP66/IP67).

Output configuration logic: All outputs need to be assigned functions (such as limit, alarm, retransmission, etc.) and function instances (such as alarm 1-4, limit 1, etc.) in the corresponding menu (Output Menu or Digital Input/Output Menu) of the "Setup Page". For example, output 1 can be configured as "Alarm 1" and output 2 can be fixed as "Limit"; Support multiple outputs associated with the same functional instance, such as alarm 2, which can simultaneously trigger output 1 (indicator light) and output 5 (buzzer).

(3) Core control and protection functions

PID control: supports hot/cold control, switch control, P, PI, PD, PID control algorithms (not specific to limit controllers), with automatic tuning function, can be started through "Operations Page" or configuration software, sampling rate input 10Hz, output 10Hz, control accuracy is affected by input sensor accuracy, calibration status and load characteristics, calibration accuracy is ± 0.1% range ± 1 ° C (0.2% for S-type thermocouples, 0.2% for T-type thermocouples below -50 ° C) at rated ambient temperature (25 ° C ± 3 ° C) and rated line voltage, minimum range 1000 ° F (540 ° C), maximum temperature stability ± 0.1 ° F/° F (± 0.1 ° C/° C) Environmental temperature rise.

Limit protection: As the core function, it supports high/low limit or dual limit monitoring. The limit upper and lower limits (Lh. s, LL. s), hysteresis value (L.hy, 0.001-9999 ° F/° C, default 3 ° F or 2 ° C), and limit sides (L.sd, high, low, or dual sides) can be set in the "Setup Page Limit Menu"; When the process value exceeds the limit range, output 2 (Form A relay) loses power, cuts off the load power supply, and maintains a locked state, requiring manual reset (through the Reset button, digital input, or communication command); Support limit reset source configuration (sfn. a, such as digital input, function keys) to ensure that normal operation can only be restored after troubleshooting.

Alarm function: Supports 4 sets of alarms (1-4), which can be configured as process alarms (high/low alarms, deviation alarms, etc.). Set the alarm type (a.ty), source (sr.a, such as analog input 1-2), upper and lower limits (a.hi, a.Lo), hysteresis value (a.hy), logic (a.Lg, power on alarm or power off alarm), latch (a.La, whether to manually clear), blocking (a.bL, whether to block alarm when starting or setting value changes), mute (a.si, whether to support mute), delay time (a.dL, 0-9999 seconds) and other parameters in the "Setup Page Arm Menu"; When an alarm is triggered, it can be notified through output actions (such as indicator lights, buzzers) or communication signals. Locked alarms need to be cleared through the "Clear Alarm (a.CLr)" command, and silent alarms need to pause output through the "Silence Alarm (a.sir)" command.

(4) Communication function

Support protocols and ports

Modbus RTU: Supports EIA-485 (Port 1/2) and EIA-232 (Port 2), with Port 1 supporting Standard Bus by default and switchable to Modbus RTU; Modbus addresses 1-247 (Standard Bus addresses 1-16), baud rates of 9600, 19200, 38400bps, parity bits none/odd/even, data bits 8, stop bit 1; Supports 16 bit register read and write, floating-point parameters occupy 2 registers, default low byte first (can set "Modbus Word Order" to Lohi or hiLo in the "Setup Page Communications Menu"); Supports Map 1 (compatible with old models) and Map 2 (compatible with new features), and recommends using Map 2 for new applications.

EtherNet/IP ™ Compared to Modbus TCP: only supported on port 2, requires configuration of IP address (fixed or DHCP), subnet mask, gateway, supports 10/100Mbps Ethernet, and can run both protocols simultaneously; CIP implicit assembly (input/output member count 1-20), explicit communication supports Class/Instance/Attribute addressing, compliant with ODVA standards.

DeviceNet ™: Port 2 support, node addresses 0-63, baud rates 125, 250, 500kbps, supports Quick Connect, CIP implicit assembly input/output members up to 200, explicit communication for configuration and diagnosis.

Profibus DP: Port 2 support, addresses 0-126, maximum baud rate of 12Mbps, supports DP-V0 (cyclic data exchange) and DP-V1 (non cyclic data exchange, used for configuration and diagnosis); GSD file configuration is required, supporting up to 32 devices per network segment, with a maximum transmission distance of 1200 meters (EIA-485), and a terminal resistance configuration option (150 Ω).

Communication configuration and tools: All communication parameters need to be configured in the "Setup Page Communications Menu" (such as protocol, address, baud rate, IP parameters, etc.); Can be accessed through Watlow PM LEGACY ™ The Limit Configurator software (free download from the official website) enables communication between the PC and the controller, supporting online configuration, parameter backup/recovery, device scanning, and other functions; During the communication process, attention should be paid to cable selection (such as using twisted pair for EIA-485, avoiding parallel wiring with power lines), terminal resistance (only network end devices need to be connected to a 120 Ω resistor), and grounding isolation (to prevent grounding loops).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

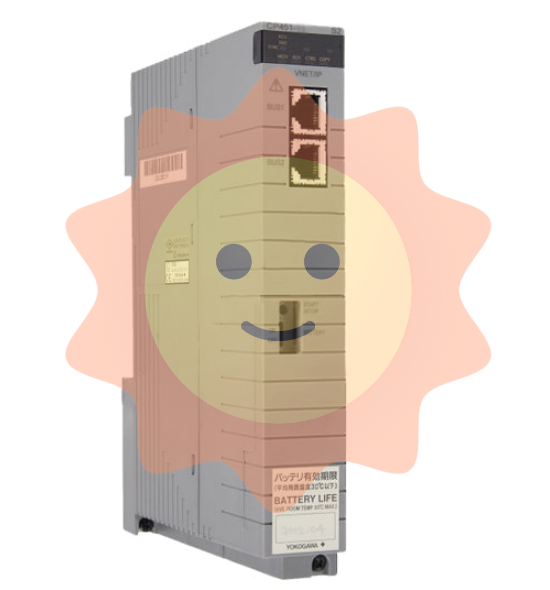

- YOKOGAWA

- TRICONEX

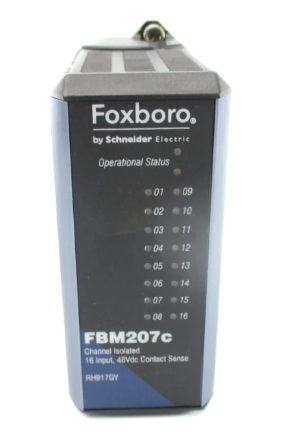

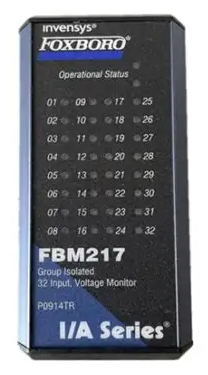

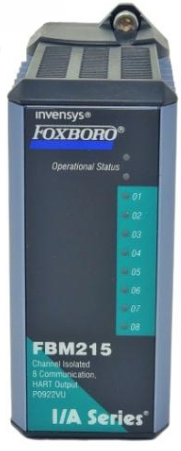

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com