Yokogawa AQ6361 Optical Spectrum Analyzer

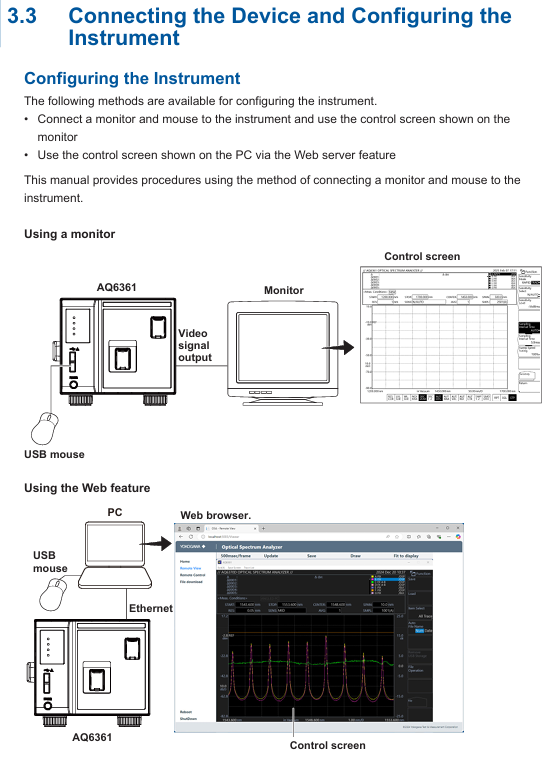

External device connection: PC connects devices through Ethernet/USB, monitor connects devices through Video OUT (XGA), mouse/keyboard connects through USB interface (supports USB HID Class 1.1 standard devices).

Software device registration and connection:

|Step | Operation Content|

|1 | Start AQ6361, enter the device connection window, click "Add" for the first connection, and select the communication method (Ethernet/USB)|

|2 | Click "Search" to search for devices, check the measuring instrument (such as AQ6361) and external devices, and click "Register" to complete the registration|

|3 | Check the target device in the registration list and click "Next" to enter the measurement and display settings window|

Key parameter configuration:

RAM data channel settings: Import symbol definition files (. a2l format) in the "Measurement Setting" window, or manually enter symbols, addresses, and data types to add RAM data channels;

Time reference synchronization: Check "Relative time" in "DAQ Setting", synchronize external devices based on the measuring instrument clock, and configure the data saving path (default: C: Users Username Documents YOKOGAWA IS8000).

(2) Startup and calibration process

Startup steps:

|Step | Operation Content|

|1. Connect the power cord, turn on the "MAIN POWER" switch on the back, and the front POWER light will turn orange|

|After waiting for a few seconds, press the "POWER" switch on the front, the light turns green, the device starts and initializes (displaying STEP 1/9 to STEP 9/9)|

|After initialization, enter the measurement interface and preheat for 1 hour before performing wavelength calibration|

Wavelength calibration (key step to ensure measurement accuracy):

Built in light source calibration (- L1 model): Connect the optical input and calibration output with 9.5/125 μ m single-mode fiber, enter "SYSTEM>Wavelength Calibration>Built in Source", click "Execute", and the calibration takes about a few minutes;

External light source calibration: Supports laser type (such as DFB-LD) or gas chamber absorption line type external light sources. After connection, set the wavelength in "External Laser/External Gas Cell" and perform calibration;

Attention: If the wavelength error exceeds ± 5nm, it is necessary to contact the Yokogawa dealer for re adjustment, as it cannot be calibrated through the built-in light source.

Resolution calibration: Use a stable single-mode laser source (output power ≥ -20dBm, linewidth ≤ 5MHz), connect it, enter "SYSTEM>Res BW Calibration", click "Execute" to complete the calibration, and the device will automatically correct the equivalent noise bandwidth after calibration.

(3) Measurement Execution and Data Management

Measurement condition setting:

Select the device in the "Device Control" panel, configure parameters such as sampling rate, trigger mode, sensitivity, and ensure that the measurement cycle of external devices (such as optical amplifiers) matches the pulse frequency of the device;

Supports three modes: "Single Sweep", "Repeat Sweep", and "Auto Sweep". Auto mode can automatically optimize measurement conditions.

Measurement operation:

|Operation | Function Description|

|Monitor Start | Start measurement (only monitors, does not record data)|

|Record Start | Start Record (Synchronize measurement and recording when monitoring is not started)|

|Record Stop | Stop recording (measurement continues)|

|Monitor Stop | Stop measurement (when recording has not stopped, synchronously stop measurement and recording)|

Data saving and loading:

The data is automatically saved in. mf4 format (including waveform and RAM data), and the default path can be modified in "DAQ Setting";

When loading data, the software opens the. mf4 file or loads the. wdf (waveform) and. mdf (RAM data) files offline, and the software automatically aligns the timeline.

Maintenance and troubleshooting

(1) Daily maintenance

Cleaning requirements:

Equipment casing: Wipe with a clean dry cloth after power failure, and prohibit the use of volatile chemicals (to prevent fading and deformation);

Optical interface: Clean the end face of the optical connector with a cotton swab dipped in pure alcohol to ensure that there is no dust (dust may affect optical performance and even damage the monochromator).

Regular inspection:

|Check project | cycle | operation content|

|Wavelength accuracy check | Regular | Use a light source with known wavelength accuracy (such as a gas laser) to measure the spectrum and confirm that the center wavelength error of THRESH 3dB is within the specified range|

|Level accuracy inspection | Regular | Using a 1310nm/1550nm light source, compare the peak level measured by the equipment with the reading of the optical power meter, and ensure that the error meets the specifications|

|Firmware Update | On Demand | Download the latest firmware from Yokogawa's official website and update via USB or Ethernet (power off is prohibited during update to avoid device failure to start)|

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

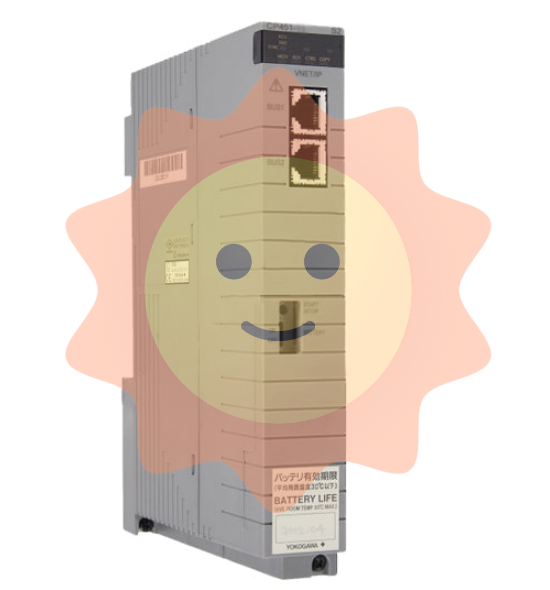

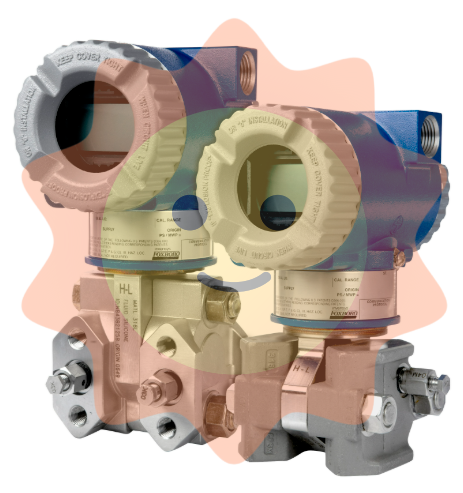

- YOKOGAWA

- TRICONEX

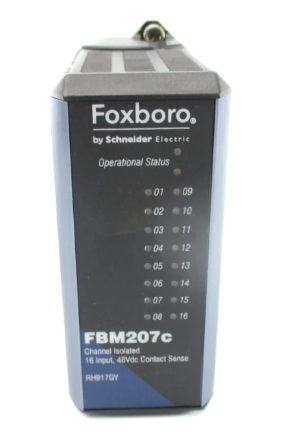

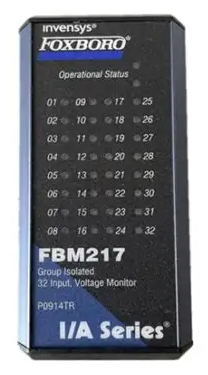

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com