Yokogawa IS8000 Integrated Software ECU Monitoring and Synchronization Function

Yokogawa IS8000 Integrated Software ECU Monitoring and Synchronization Function

Functional positioning

The ECU monitoring synchronization option (/EM1 or - EM1) is an extended function of the IS8000 integrated software, which can synchronize the waveform measured by waveform measuring instruments (such as DL950, SL2000) with the RAM data obtained by the ECU monitor (such as RAMScope) based on the sampling clock for display, supporting joint data analysis.

Core functions and system configuration

(1) Functional principles and core characteristics

Synchronization principle: The sampling clock generated by the waveform measuring instrument is used as a synchronization signal to be transmitted to the ECU monitor, and the measurement data of both parties is loaded through IS8000 software to achieve synchronous display of waveform and RAM data on the PC side.

Core functions:

|Functional Category | Specific Description|

|Synchronized display | ECU monitor RAM data and waveform measurement instrument waveform data are aligned and displayed based on sampling clock|

|Measurement Control | Supports measurement start/stop and recording of start/stop operations for ECU monitors and measuring instruments|

|Data Storage | Automatically merge RAM data with waveform data and save them as. mf4 format files; Support saving symbol definitions as XML files|

|Offline synchronization | Supports offline loading of saved waveform data (. wdf format) and RAM data (. mdf format), achieving timeline synchronization by aligning the "FirstData" points|

(2) System configuration requirements

Hardware compatibility:

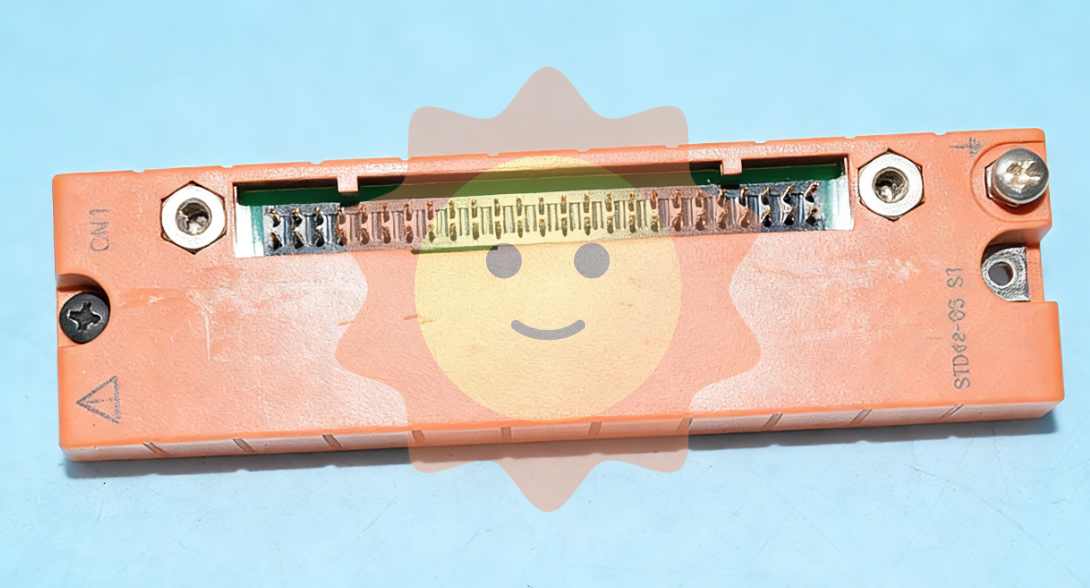

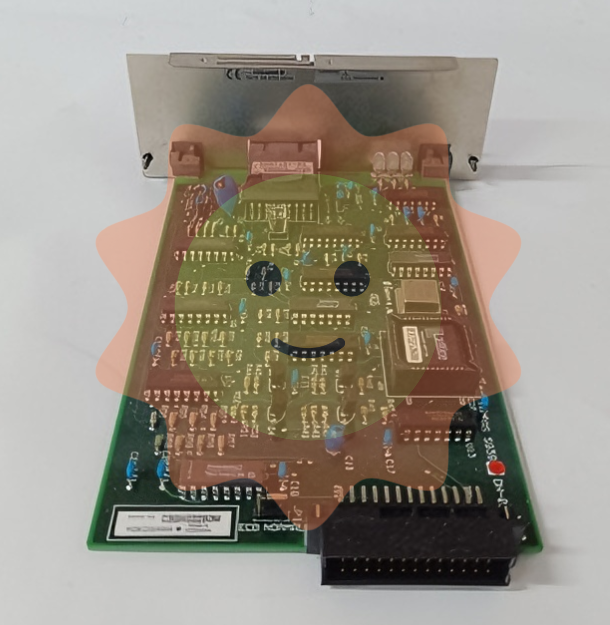

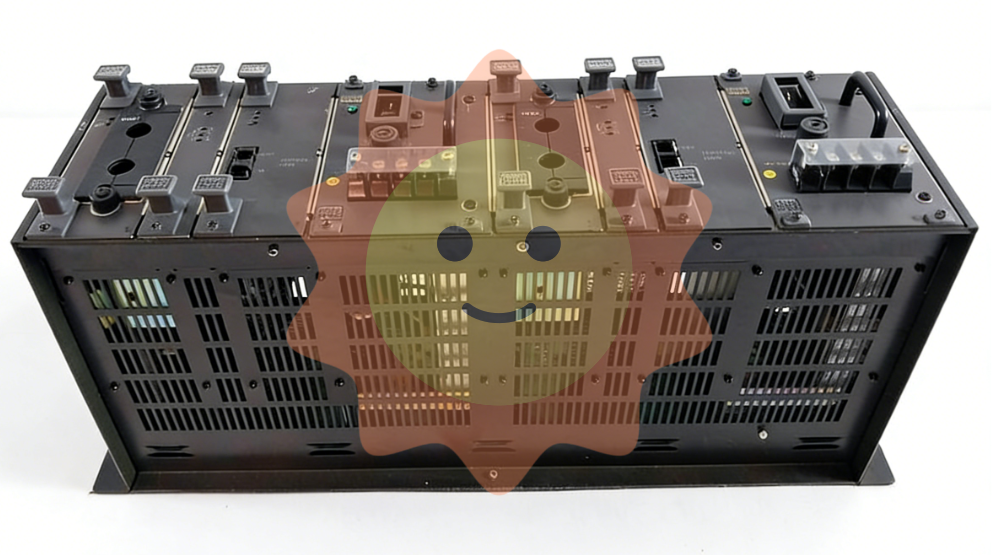

ECU monitor: Supports RAMScope GT122, GT170EXG (RAM measurement module only), the latest compatible models need to refer to Yokogawa official website;

Waveform measuring instruments: Yokogawa DL950, SL2000 (require installation of input modules that match the measurement target);

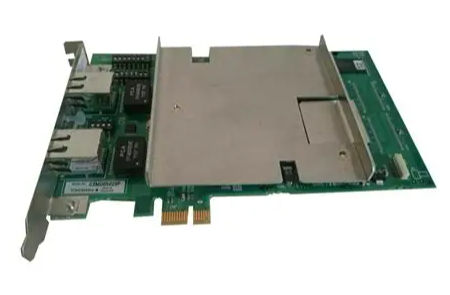

PC communication interface: It needs to support USB (USBTMC, VISA protocol) or Ethernet (VXI-11, HiSLIP protocol), and a dedicated USB driver needs to be installed (which can be downloaded from) https://tmi.yokogawa.com/library/ Download).

PC system requirements: According to the usage scenario, it can be divided into two types of configurations, as follows:

|Usage scenario | CPU requirements | Memory requirements | SSD requirements | Operating system|

|10G Ethernet communication/trigger DAQ (up to 24 hours continuous recording) | Intel Core i7-10700K and above (4 cores, 8 threads, 4.7 GHz+) | 16 GB and above | 512 GB and above (NVMe SSD recommended, read/write speed 3 GB/s+) | Windows 10 64 bit Windows 11|

|1G Ethernet/USB communication/offline analysis | Intel Core i5-10210U and above (4 cores, 8 threads, 4.2 GHz+) | 8 GB and above | 256 GB and above (read/write speed of 400 MB/s+) | Windows 10 64 bit Windows 11|

Additional requirements: Screen resolution of 1366 × 768 or higher (100% zoom), mouse and printer (optional) are required.

Operation process: from configuration to data management

(1) Hardware connection and software configuration

Hardware connection steps:

Connect the measuring instrument to the ECU monitor: Connect the sampling clock output terminal (CLKO, with GND) of DL950/SL2000 to the synchronization signal input terminal of the ECU monitor;

Connect PC: The measuring instrument is connected to the PC via Ethernet or USB, and the ECU monitor is connected to the PC via USB;

Special note: If the ECU monitor is RAMScope, it is necessary to first configure RAM measurement related settings through RAMScope V/VP and verify the data acquisition function. Close the software before connecting to IS8000.

Software device registration and connection:

|Step | Operation Content|

|1 | Start the IS8000 software, click on "DAQ" to enter the device connection window|

|When connecting for the first time, click "Add", select the communication method (Ethernet/USB), and then click "Search" to search for the device|

|3 | Check the measurement instrument (such as DL950) and ECU monitor (such as RAMScope) in the search results, and click "Register" to complete the registration|

|4. Check the target device in the registered device list and click "Next" to enter the measurement and display settings window|

RAM data measurement channel settings:

Click "Add Channel" in the "Measurement Setting" window and import the symbol definition file (in. a2l format, generated by RAMScope VP) through "Edit>Import File", or manually enter the symbol, address, and data type;

After importing, click "Add" to add the RAM data channel to the channel list. After confirmation, click "Next" to enter DAQ settings.

Time reference synchronization setting:

Check 'Relative time' in the 'Time Base' section of the 'DAQ Setting' window (based on measuring instrument clock synchronization ECU monitor);

Configure the record saving path (default path: C: Users Username Documents YOKOGAWA IS8000), file name rules, etc. Click "OK" to complete the configuration and enter the DAQ control interface.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

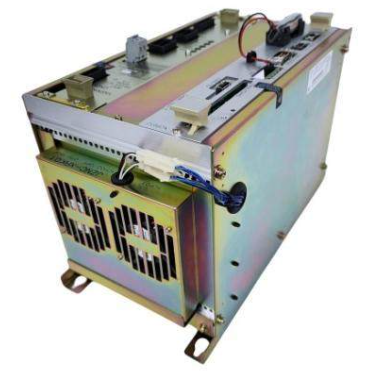

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

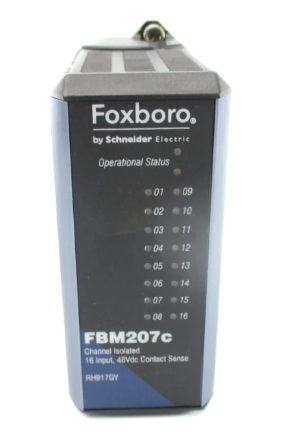

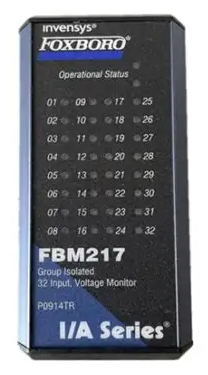

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

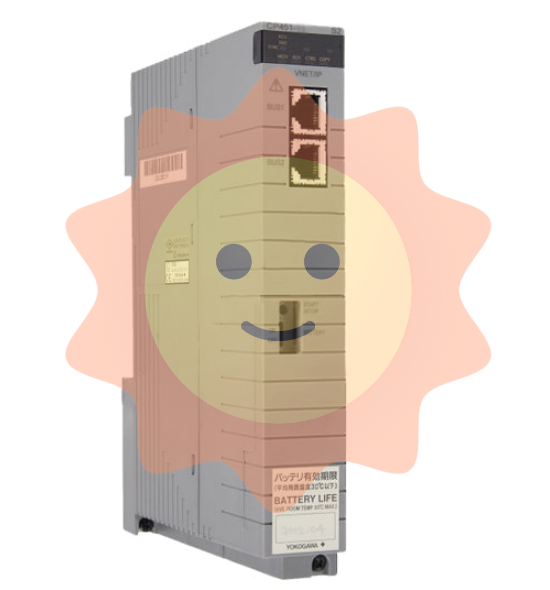

- YOKOGAWA

- TRICONEX

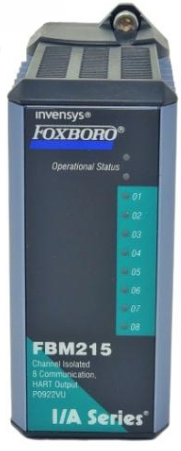

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com