Yokogawa IS8000 Integrated Software ECU Monitoring and Synchronization Function

(2) Measurement Execution and Data Management

Measurement condition setting:

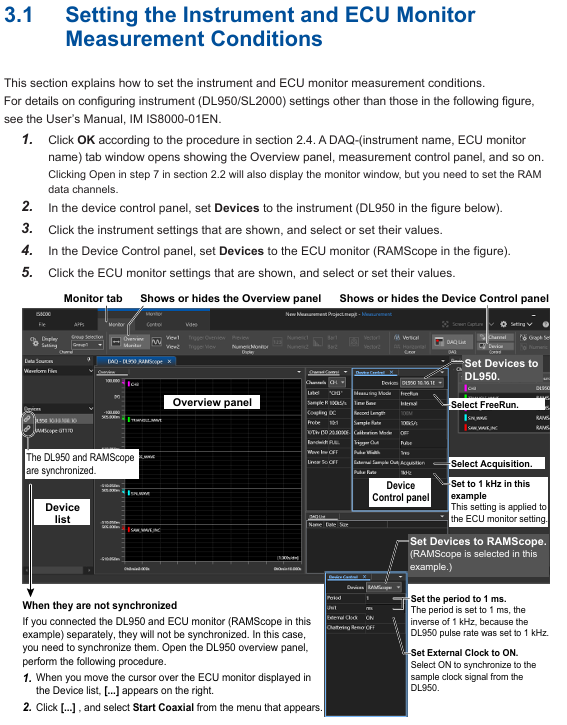

In the "Device Control" panel of the DAQ control interface, select the measuring instrument and ECU monitor respectively, and configure parameters (such as DL950 sampling rate, trigger mode, and RAMScope measurement cycle);

Key synchronization requirements: The measurement cycle of the ECU monitor should match the pulse frequency of the measuring instrument (such as DL950 pulse rate of 1 kHz corresponding to RAMScope cycle of 1 ms), and the "External Clock" should be turned on to synchronize the external clock.

Measurement and recording operations:

|Operation steps | Function description|

|1 | Click on "Monitor Start": Start measurement (only monitoring, no data recording)|

|2 | Click on "Record Start": Start recording (if monitoring is not started, measurement and recording will be synchronized)|

|3 | Click "Record Stop": Stop recording (measurement continues, monitoring can continue)|

|4 | Click "Monitor Stop": Stop the measurement (if the recording is not stopped, the measurement and recording will be stopped synchronously)|

Caution: Do not operate the measuring instrument panel during the recording period; PC needs to disable standby/sleep mode to avoid software interruption; When there is a connection error, the measuring instrument needs to be restarted.

Data saving and loading:

Data saving: After stopping recording/measurement, the data is automatically saved as a. mf4 format file. If "Automatically open the last saved file" is checked, the file will be automatically opened after saving;

Data loading: Refer to the IS8000 user manual (IM IS8000-01EN), open the saved. mf4 file (or. wdf and. mdf files in offline scenarios) in the software, and the software will automatically align the timeline to display the data.

(3) Offline synchronization operation (Appendix supplement)

For scenarios without real-time connectivity requirements, the offline synchronization process is as follows:

Connect the measuring instrument and ECU monitor according to the hardware connection requirements, and disconnect from the PC;

Configure measuring instruments separately (set external sampling clock, pulse rate, trigger mode) and ECU monitors (synchronize external clock, monitoring time needs to be longer than measuring instruments);

Start the ECU monitor (enter clock standby) → Press the "START" button on the measuring instrument (output sampling clock, ECU starts to acquire RAM data) → Press the "STOP" button on the measuring instrument (stop clock and RAM data acquisition) → Stop the ECU monitor;

Save the measurement instrument data (in. wdf format) and ECU data (in. mdf format) separately, load the two files in IS8000, and synchronize the software display by aligning the "FirstData" points.

Usage restrictions and precautions

License restriction: A single license supports the use of this option on two PCs simultaneously; It is prohibited to connect multiple PCs to the same measuring instrument at the same time.

Communication limitation: When controlling measuring instruments, only one communication interface (Ethernet/USB) is supported at a time; Prohibit the simultaneous use of multiple interfaces.

Operation taboos: It is prohibited to operate the measuring instrument panel during data recording; The PC needs to disable standby/sleep mode, otherwise it may cause software interruption.

Fault handling: If there is a connection error, prioritize restarting the measuring instrument; If synchronization is abnormal, check the matching between the sampling clock connection and parameters (such as pulse rate and measurement period).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

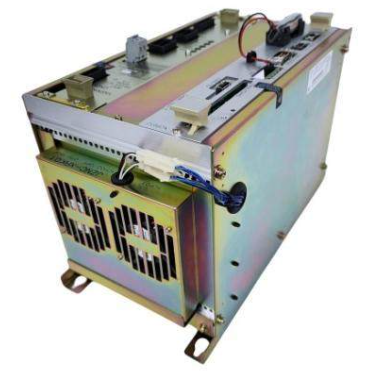

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

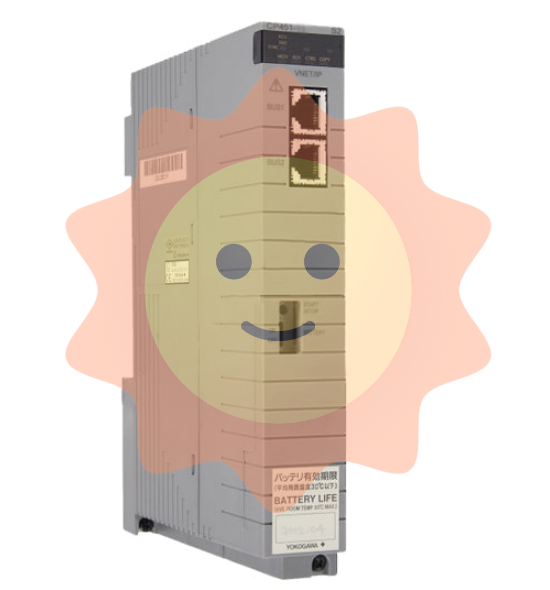

- YOKOGAWA

- TRICONEX

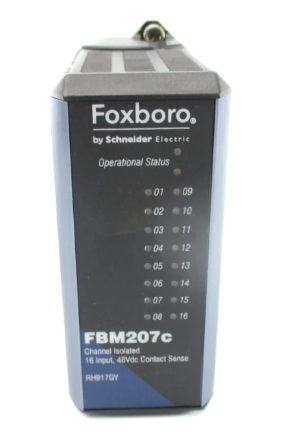

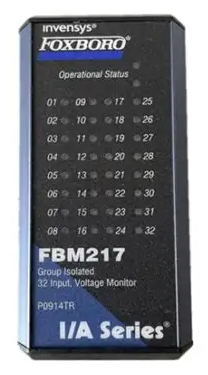

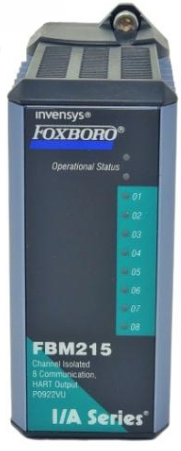

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com