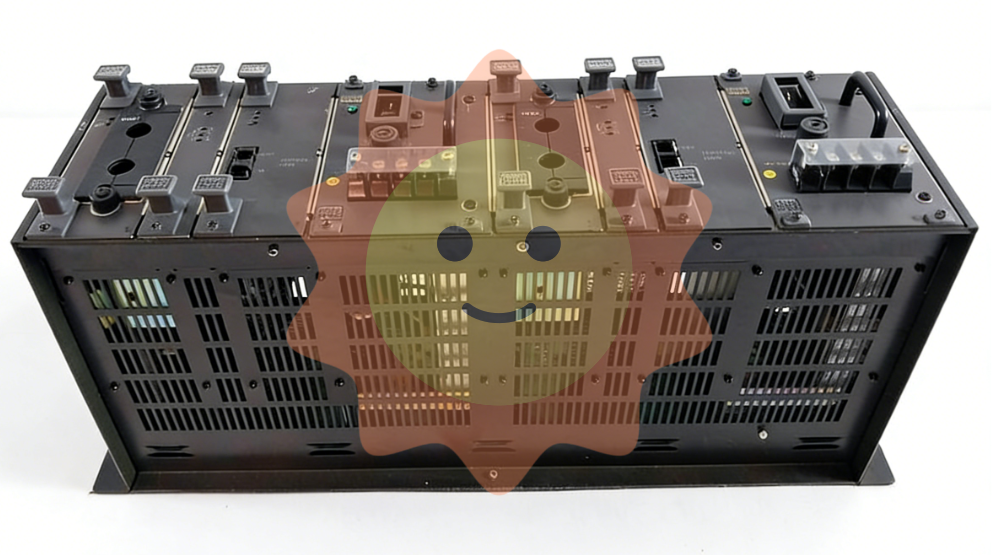

TOSHIBA e-STUDIO 7516AC Color Multifunctional Printer

Core function: Integrated with four basic functions of copying, printing, scanning, and faxing, supporting high-capacity and high-speed document processing, while also having the ability to customize UI and automate workflow, adapting to personalized office scenarios of different enterprises.

Access control: Supports multi-dimensional authentication (device authentication, Windows domain authentication, LDAP server authentication, card/NFC authentication), MAC/IP address filtering (10 groups each), role-based access control (RBAC), only authorized users can operate core functions; Simultaneously supporting secure PDF and firmware digital signatures to prevent malicious software attacks and unauthorized firmware tampering.

Compliance certification: Through HCD-PP certification and CC certification (ISO/IEC15408), it complies with internationally recognized information security assessment standards and is suitable for industries sensitive to data security, such as finance and government.

environmental performance

Certification standard: Compliant with ENERGY STAR ® V3.0 certification, EPEAT Gold registration, using RoHS compliant materials, and using recycled plastic for the body to reduce environmental impact.

Energy saving design: Supports super sleep mode (with a power consumption of only 0.6W), low monthly average energy consumption (TEC value), and reduces operating electricity costs; Equipped with e-Bridge Plus green information function, it can display the company's environmental contribution data (such as reduced carbon emissions) on the touch screen, guiding employees to use the equipment efficiently.

Optional accessories

Accessory category, model, and function description

GR1330 accessory tray for auxiliary operation accessories, used to place small operating tools or consumables

GR9000 Bluetooth keyboard simplifies device side text input operations

GR1340 10 key numeric keypad improves numerical input efficiency

Binding and output accessories MJ1111B 50 page console stapler, supporting single/multi page stapling binding

MJ1112B 50 page saddle stitch stapler, supporting saddle stitch binding and folding of picture books and manual documents

MJ6106N punching unit (compatible with MJ1111B/MJ112B), supports document punching processing

KA6551 side paper tray provides additional document output channels to avoid confusion with the main tray

Connect and secure accessories GD1370N fax unit/second fax line, expand fax function or add fax line redundancy

GN4020 wireless LAN/Bluetooth module, enabling wireless connection of devices and adaptation to Bluetooth peripherals

GE1230 FIPS 140-2 certified self encrypting hard drive (SED) meets high security level data storage requirements

GP1080 IPsec Security enabler, activates device IPsec encryption function

Function extension accessory GS1080NODE embedded OCR enabler (authorized by seat), supporting the conversion of scanned documents into editable Office formats

GS1090NODE multi workstation printing enabler (authorized by seat), supports users to obtain printing tasks on any device with card authentication

Paper expansion accessory MP2502B 2500 large capacity feeder (only supports LT size), significantly increasing paper reserve capacity

Troubleshooting and Maintenance

Fault code system

Indoor unit fault codes: covering communication faults (such as E03: indoor remote control communication interruption, E04: indoor outdoor communication interruption), sensor faults (such as F01: TCJ sensor open/short circuit, F10: TA sensor fault), hardware faults (such as P10: indoor overflow, P12: DC fan fault), each code corresponds to a clear troubleshooting direction (such as checking line connections, sensor resistance, hardware components).

Outdoor unit fault codes: including communication faults (E06: indoor unit disconnection, E23: outdoor outdoor communication interruption), abnormal pressure/temperature (P03: high exhaust temperature, P20: high pressure protection activated), compressor faults (H01: compressor overcurrent, H02: compressor lock), which need to be checked in conjunction with the 7-segment display on the external unit interface board and manual steps.

Test run operation

Wired remote control (RBC-AMT series): Press and hold the 【 TEST 】 button for more than 4 seconds to enter the test mode, press 【 MODE 】 to switch between 'cooling/heating', and the test will automatically exit after 60 minutes. During this period, the temperature cannot be adjusted, and the fault detection will take effect normally.

Wireless remote control: After turning on, wait for 1-5 minutes (5 minutes for the first power on), press [ON/OFF] to start, select "cooling/heating" for [MODE], select "HIGH" for [FAN], activate the test through a specific temperature setting sequence (such as cooling: 62 ° F → 64 ° F → 62 ° F), and the indicator light flashes for 10 seconds before starting.

Regular maintenance checklist

Daily maintenance: Clean the filter screen weekly (standard filter screen can be washed with water), check the paper capacity indicator, check the remaining consumables (toner, toner cartridge) monthly, and confirm that the safety lock and certification functions are normal.

Quarterly maintenance: Clean the scanning platform and feeder rollers, check network connection stability, test IPsec and data encryption functions; Every year, professionals inspect the health of SED hard drives, calibrate sensors (TA/TC1/TC2), and check the operating status of environmental protection modes.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

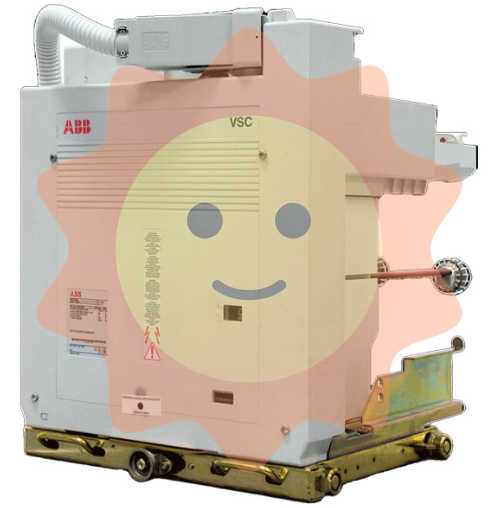

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

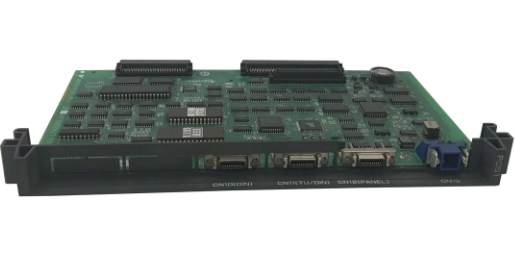

- PLC

- DCS

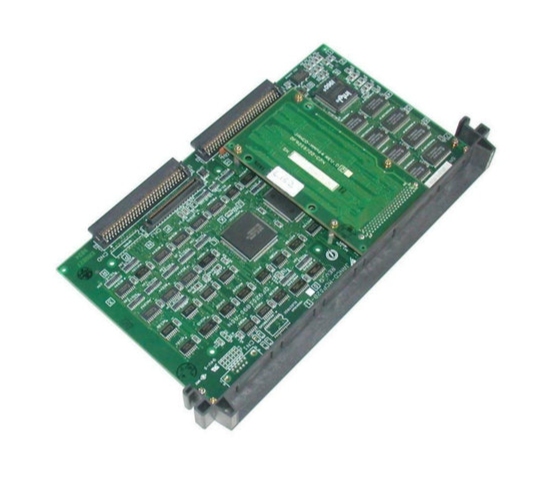

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

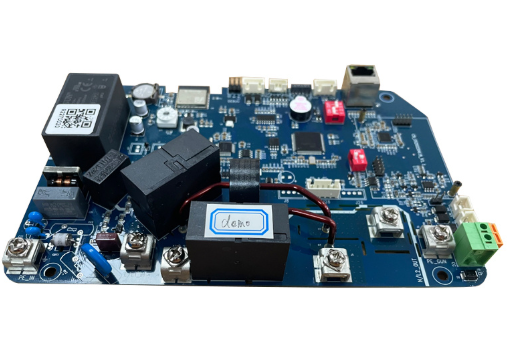

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

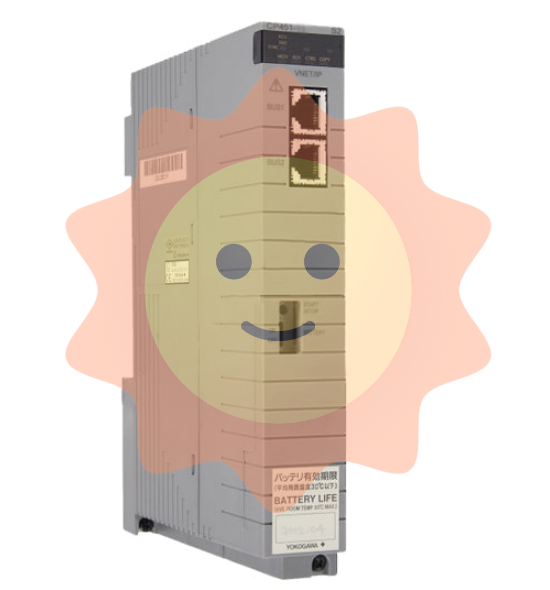

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

Email:wang@kongjiangauto.com