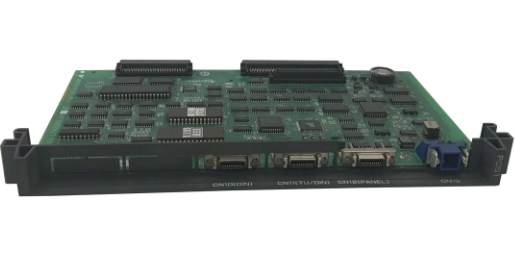

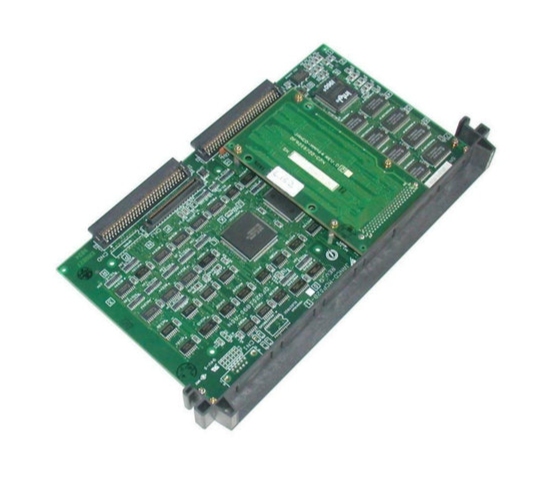

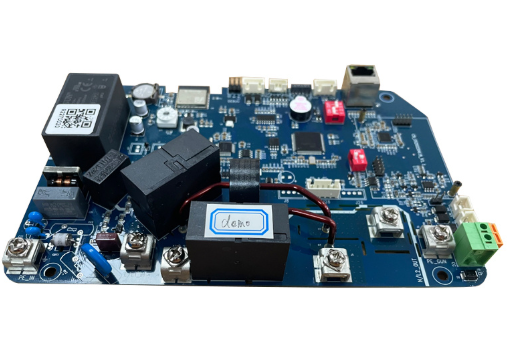

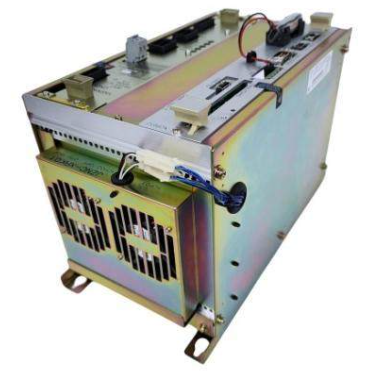

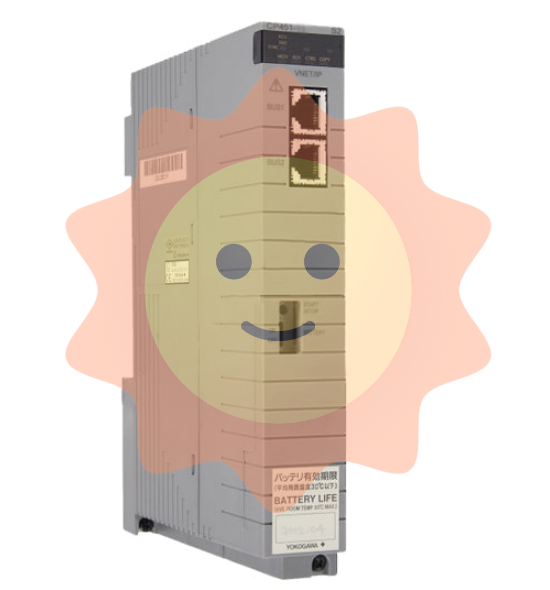

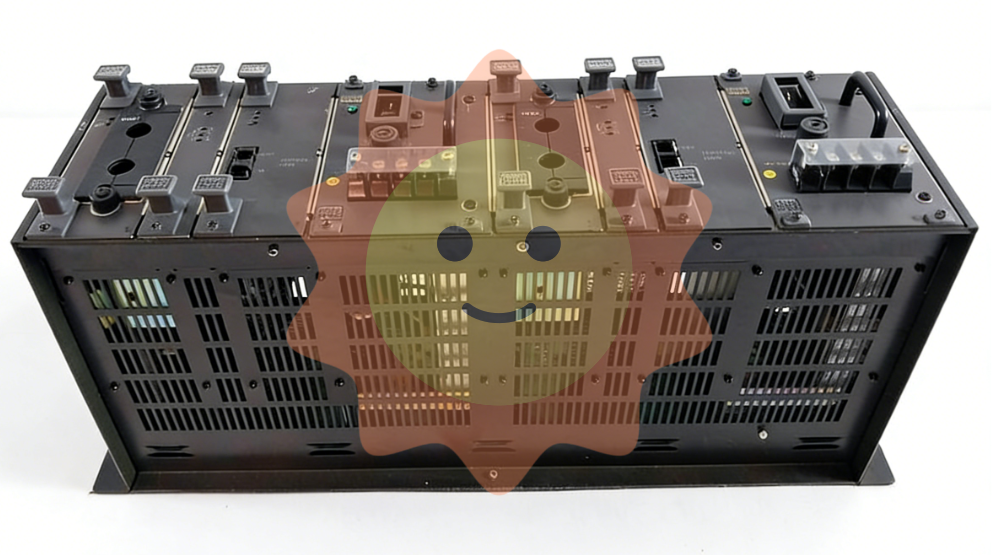

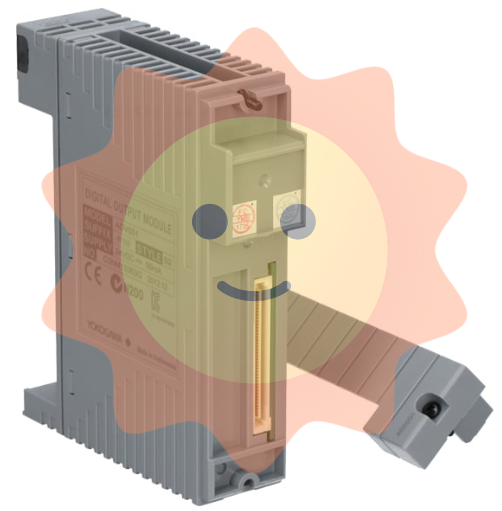

ABB Sace BSD series brushless servo drive

ABB Sace BSD series brushless servo drive

Equipment Overview

1. Specification of servo amplifier

Model Applicable Motor Capacity Power Type Key Parameters

BSD0100 BSM0100 (100W) single-phase 200-230V carrier frequency 10kHz, overload capacity 300%/about 3 seconds

BSD0200 BSM0200 (200W) single-phase 200-230V-

BSD0400 BSM0400 (400W) single-phase 200-230V-

BSD0750 BSM0750 (750W) single-phase/three-phase 200-230V-

BSD1000 BSM1000 (1000W) three-phase 200-230V-

BSD1500 BSM1500 (1500W) three-phase 200-230V-

BSD2000 BSM2000 (2000W) three-phase 200-230V-

2. Specification of servo motor

Series model Capacity Rated speed Rated torque Encoder

Low inertia BSM0100 100W 3000r/min 0.318N · m 17 bit serial

Low inertia BSM0200 200W 3000r/min 0.637N · m 17 bit serial

Low inertia BSM0400 400W 3000r/min 1.27N · m 17 bit serial

Low inertia BSM0750 750W 3000r/min 2.39N · m 17 bit serial

Medium inertia BSM1000 1000W 2000r/min 4.77N · m 17 bit serial

Medium inertia BSM1500 1500W 2000r/min 7.16N · m 17 bit serial

Medium inertia BSM2000 2000W 2000r/min 9.55N · m 17 bit serial

3. Model coding rules

Servo amplifier: Only specify power, such as the power corresponding to "XXXX" in "BSDXXXX" (0100=100W).

Servo motor: format is "BSMXXXXXX", where "XXXX"=power, "C"=shaft type (C=keyway, L=flat shaft), "N/B"=brake (N=none, B=present), "00/01"=option (00=none, 01=oil seal).

Installation requirements

1. Installation of servo motor

Project Requirements Remarks

Storage environment temperature -20 ° C~60 ° C, humidity 10% -90% RH (no condensation), the same requirement applies when equipped with gear heads

Working environment temperature -10 ° C~40 ° C, humidity 10% -90% RH (no condensation), temperature with gear head 0 ° C~40 ° C

The installation direction can be horizontal, downward, or upward (in accordance with IEC standards IMB5/L51, etc.), and the encoder end should not be subjected to force

Load limit radial load (127N-510N), axial load (19N-253N) refer to Table 2-5 in the document, such as BSM0100 radial 127N

Cable protection for mobile scenarios requires drag chains with a maximum bending radius to avoid oil/water immersion

2. Installation of servo amplifier

Project Requirements Remarks

Storage environment temperature -20 ° C~85 ° C, humidity 10% -90% RH (no condensation), altitude ≤ 1000m, no dust/corrosive gas

Working environment temperature -10 ° C~55 ° C, humidity 10% -90% RH (no condensation), non drip/dust-proof, multiple installations require spacing

Installation direction Upright direction (horizontal marked with "BSD") Heat dissipation requirements

When the installation spacing is ≥ 50mm at the top and ≥ 40mm at the bottom, and the spacing between multiple parallel units is ≥ 5mm and < 5mm, the rating needs to be reduced to 80% ED

Leave ≥ 70mm (for easy operation) for wiring in the front space, with a depth of 165mm for 1.0kW and below, and 185mm for 1.5kW and above

Wiring specifications

1. Power wiring

Equipment power type, wiring terminal voltage range, frequency

Servo amplifier (0.4kW and below) single-phase L1, L2 200-230VAC (-10%~+10%) 50/60Hz

Servo amplifier (0.75kW) single-phase/three-phase L1, L2 (single-phase); L1, L2, L3 (three-phase) 200-230VAC (single-phase -10%~+10%, three-phase -15%~+10%) 50/60Hz

Servo amplifier (0.85kW and above) three-phase L1, L2, L3 200-230VAC (-15%~+10%) 50/60Hz

Control power supply (all models) single-phase sL1, sL2 200-230VAC (-10%~+10%) 50/60Hz

2. Key wiring taboos

Do not connect the commercial power supply (200V) to the U/V/W terminals of the servo motor (as it may burn the motor).

Do not connect the grounding wire (E) to the U/V/W terminal, and do not connect the U/V/W terminal in reverse (which may cause fire/malfunction).

It is prohibited to conduct voltage withstand, megaohm, and buzzing tests on the encoder terminal (CN2) as it may damage the encoder.

The distance between the serial I/O (CN1) and the motor power cable should be ≥ 10cm (to avoid interference).

Test Run

1. Three stage testing process

Key inspection items for stage testing content

The first stage servo amplifier and motor are tested separately (not connected to the machine). 1. Power wiring (L1/L2/L3); 2. Motor power supply (U/V/W) and encoder wiring; 3. Motor rotation direction (parameter # 04); 4. No alarm

In the second stage, connect to the upper control system (not connected to the machine). 1. Connect the signal lines of the upper system; 2. I/O signals (such as emergency stop EMG, overtravel ± OT); 3. Motor speed/torque (in accordance with instructions)

The third stage of testing after installing the machine (final state): 1. The firmness of the motor installation; 2. Machine travel; 3. Servo parameter adjustment (refer to Chapter 6); 4. Positioning accuracy

2. Origin regression requirements

After power failure and restart, the motor needs to be rotated at a speed of ≤ 100r/min for 372 ° or more (approximately 1.04 rpm) in order to correctly detect the Z-phase.

Parameter settings

1. Parameter configuration method

Keyboard operation: Switch to "Parameter Editing Mode" (PnO) for settings through a 4-digit 7-segment LED display and 4 buttons (MODE/ESC, SHIFT, ENT, ∧/∨).

BSD Configurator: Connected to CN3 via LAN cable (CAT. 5 direct connection), supports parameter read/write, batch transfer, and monitoring.

2. Core parameter table

Parameter number, parameter name, control mode, setting range, initial value, key role

#01 Command pulse compensation alpha position 1-32767 16 electronic gear ratio molecule, converting command pulse to mechanical stroke

#02 instruction pulse compensation β position 1-32767 1 electronic gear ratio denominator

#03 Pulse train input form: Position 0 (command pulse+symbol), 1 (forward/reverse pulse), 2 (two signals with a 90 ° phase difference), 1 matches the output type of the upper system pulse

#04 Rotation direction switching/output pulse phase all 0-30 set motor forward rotation direction (CCW/CW) and output pulse phase

#05 tuning mode position/speed 0 (automatic), 1 (semi-automatic), 2 (manual) 0 select servo gain tuning mode

#06 Load inertia ratio position/velocity GYS: 0.0-100.0; GYG: 0.0-30.0 5.0 (BSM low power), 1.0 (BSM high power) ratio of motor inertia to load inertia

#07 Automatic tuning gain position/speed 1-20 10 Adjust servo response speed (high value, fast response but prone to vibration)

#09 Control mode switch all 0 (position), 1 (speed), 2 (torque), 3 (position) ↔ 0 fixed or switchable control mode for speed)

3. Parameter Effectiveness Rules

The parameters marked as "Power" (such as # 03, # 04, # 09) need to be powered off and restarted to take effect; Other parameters (such as # 01, # 02, # 07) take effect in real-time.

Servo adjustment and special functions

1. Tuning method

Operation points for applicable scenarios of tuning types

Automatic tuning (# 05=0) Most conventional mechanical amplifiers automatically estimate the inertia ratio and set the optimal gain

Semi automatic tuning (# 05=1) inaccurate estimation of inertia ratio, manual setting of # 06 (load inertia ratio) in scenarios, amplifier automatically calculates gain

Manual tuning (# 05=2) Automatic/semi-automatic tuning failed. Manually set # 40 (position gain), # 41 (speed response), # 42 (speed integration time), etc

2. Special adjustment function

Vibration suppression control: By setting parameters # 60- # 63 (anti resonance frequency 0-3), mechanical vibrations (such as end effector vibrations of robotic arms) are suppressed within a frequency range of 5.0-200.0Hz.

Instruction Follow Control: Parameter # 55 is set (0=none, 1=follow, 2=follow+stop compensation) to achieve zero deviation following of pulse instructions, suitable for high rigidity machinery.

Inspection and maintenance

1. Regular inspection items

Equipment inspection content inspection frequency

Servo motor 1. Mechanical coupling deviation; 2. Smoothness of axis rotation; 3. Cable damage; 4. Loosening of screws regularly (e.g. monthly)

Servo amplifier 1. Dust accumulation; 2. Abnormal noise from the cooling fan; 3. Loose terminal screws; 4. No odor/signs of overheating regularly (e.g. monthly)

2. Service life and replacement of vulnerable parts

Component Standard Life Replacement Tips

Servo amplifier main circuit capacitor 73000h (10 years), lifespan shortened when ambient temperature exceeds 30 ° C

Replace the servo amplifier cooling fan when it makes abnormal noise or stops running after 30000 hours (3 years)

Replace servo motor bearings when vibration/abnormal noise occurs after 20000-30000 hours (3-5 years)

Replace the servo motor oil seal after 5000 hours of oil leakage

3. Common alarm handling

Alarm code, alarm reason, handling measures

OC1/OC2 overcurrent 1. Check the U/V/W wiring of the motor; 2. Check if the motor is short circuited/grounded; 3. Replace the amplifier

OL overload 1. Check motor load matching; 2. Extend the acceleration and deceleration time; 3. Reduce operating frequency

HV overvoltage 1. Check the power supply voltage; 2. Connect external regenerative resistors; 3. Extend deceleration time

LV undervoltage 1. Check the power supply voltage; 2. Confirm parameter # 26 (undervoltage detection) setting; 3. Improve the power environment

RS485 communication

1. Communication specifications

Project specifications

Signal level RS485

Communication method: 4-wire half duplex, asynchronous communication

Baud rate 9600/19200/38400bps (parameter # 83 setting)

Data format: 1 start bit, 8 data bits, 1 even check bit, 1 stop bit

Station number 1-31 (parameter # 2 setting)

Connect cable LAN line (CAT. 5 direct connection)

2. Core functions

Read: Multiple monitoring data (such as speed, torque), sequence mode, I/O signals, alarm history, system status.

Write: parameters, alarm reset, parameter initialization.

Key issue

Question 1: What are the matching rules between BSD series servo amplifiers and servo motors? What are the differences in power wiring requirements for amplifiers of different capacities?

Answer:

Matching rule: The selection should be based on the principle of "consistent capacity+matching speed", and the specific corresponding relationship is shown in the table below:

Servo amplifier model applicable servo motor model motor capacity motor rated speed

BSD0100 BSM0100xxxx 100W 3000r/min

BSD0200 BSM0200xxxx 200W 3000r/min

BSD0400 BSM0400xxxx 400W 3000r/min

BSD0750 BSM0750xxxx 750W 3000r/min

BSD1000 BSM1000xxxx 1000W 2000r/min

BSD1500 BSM1500xxxx 1500W 2000r/min

BSD2000 BSM2000xxxx 2000W 2000r/min

(Note: "xxxx" represents motor shaft type, brake and options, such as BSM0100CN00=100W, keyway shaft, no brake, no options)

Differences in power wiring:

0.4kW and below (BSD0100/0200/0400): Only supports single-phase 200-230VAC, wired to L1 and L2 terminals, voltage fluctuation allowed -10%~+10%.

0.75kW (BSD0750): Supports single-phase or three-phase 200-230VAC, with single-phase connected to L1 and L2, and three-phase connected to L1, L2, and L3; Single phase voltage fluctuation -10%~+10%, three-phase -15%~+10%.

0.85kW and above (BSD1000/1500/2000): Only supports three-phase 200-230VAC, wired to terminals L1, L2, and L3, with allowable voltage fluctuations of -15% to+10%.

All models of control power supply are unified as single-phase 200-230VAC, wired to sL1 and sL2 terminals, with voltage fluctuations ranging from -10% to+10%.

Question 2: What are the core objectives and key operational steps of the three-stage testing in the testing operation of BSD series servo systems? What are the requirements to pay attention to when returning to the origin?

Answer:

Core purpose and steps of three-stage testing:

Key operational steps for the core objectives of the stage

In the first stage, verify that the servo amplifier and motor work separately and eliminate basic wiring/hardware faults. 1. Fix the motor (axis without load); 2. Connect the amplifier motor power/encoder cable (not connected to CN1); 3. Power on and check the charging LED and keyboard display; 4. Test the rotation direction of the motor (parameter # 04) and ensure there are no alarms

The communication and command response between the second stage verification and the upper control system are normal. 1. Connect amplifier CN1 to the upper system; 2. Check the I/O signals (emergency stop EMG, overtravel ± OT, brake timing); 3. Power on and output pulse/analog commands, check motor speed, rotation direction, and I/O signal recognition

The third stage verifies that the motor operates normally as a whole after installation and meets the actual working conditions. 1. Securely install the motor onto the machine; 2. Reproduce the second stage I/O signal inspection; 3. Verify that the machine travel matches the instructions; 4. Adjust servo parameters (refer to Chapter 6) to ensure positioning accuracy/no vibration

Origin regression requirements:

After power failure and restart, the motor needs to rotate 372 ° or more at a speed of * * ≤ 100r/min (approximately 1.04 revolutions, motor output shaft angle) in order to correctly detect the encoder Z phase.

If the requirements of "speed ≤ 100r/min+rotation ≥ 372 °" are not met, the Z-phase cannot be correctly identified, which may result in the motor rotating an additional circle after returning to the origin.

Question 3: In the BSD series servo system, what scenarios are the three settings (automatic/semi-automatic/manual) of core parameter # 05 (tuning mode) applicable to? How to suppress mechanical vibration through parameter adjustment?

Answer:

Tuning mode (parameter # 05) Applicable scenarios:

Tuning mode parameter # 05 setting applicable scenario operation points

Automatic tuning: Most conventional mechanical amplifiers (with stable load inertia and no special resonance) automatically estimate the load inertia ratio without manually setting # 06, directly generating the optimal gain (such as # 40/# 41/# 42)

Semi automatic tuning 1. Inaccurate load inertia estimation scenarios (such as large load fluctuations, high friction, and applications with thrust) 1. Manually set # 06 (load inertia ratio, read or calculated through keyboard monitoring mode); 2. The amplifier automatically calculates gain based on # 06

Manual tuning 2 automatic/semi-automatic tuning failure scenarios (such as obvious mechanical resonance and high rigidity requirements) 1. Manually set # 40 (position controller gain), # 41 (velocity response), and # 42 (velocity integration time); 2. Optimize with # 45 (feedforward filtering) and # 46 (torque filtering); 3. Use BSD Configurator to monitor waveforms

Parameter adjustment method for suppressing mechanical vibration:

Method 1: Enable vibration suppression control (position control only):

First, optimize the servo gain according to Chapter 6 "Basic Adjustment" (ensuring no basic vibration);

Find the mechanical anti resonance frequency (5.0-200.0Hz) through the BSD Configurator servo analysis function;

Set the anti resonance frequency to parameter # 60- # 63 (anti resonance frequency 0-3), while setting # 43 (S-curve time constant, reference: anti resonance frequency<10Hz set 10ms, 10-20Hz set 5ms,>20Hz set 2-3ms).

Method 2: Use notch filter (position/velocity control):

Find the mechanical resonance frequency (through servo analysis function);

Set parameter # 56 (notch filter 1 frequency)=resonance frequency, # 57 (notch filter 1 damping)=5-20dB (to avoid excessive control instability);

If there are two resonance points, repeat step 2 to set # 58 (filter 2 frequency) and # 59 (filter 2 damping).

Method 3: Adjust gain and filtering:

Reduce # 07 (automatic tuning gain) by 1-2 levels (decrease response speed, suppress vibration);

Increase # 46 (torque filtering time constant) by 0.01-0.05ms (smooth torque command, reduce mechanical impact).

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

Email:wang@kongjiangauto.com